RO-RA’S MECHANISMS FOR THE AIRCRAFT CABIN

EASY OPENING AND CLOSING OF THE BAGGAGE RACKS IN AIRCRAFT

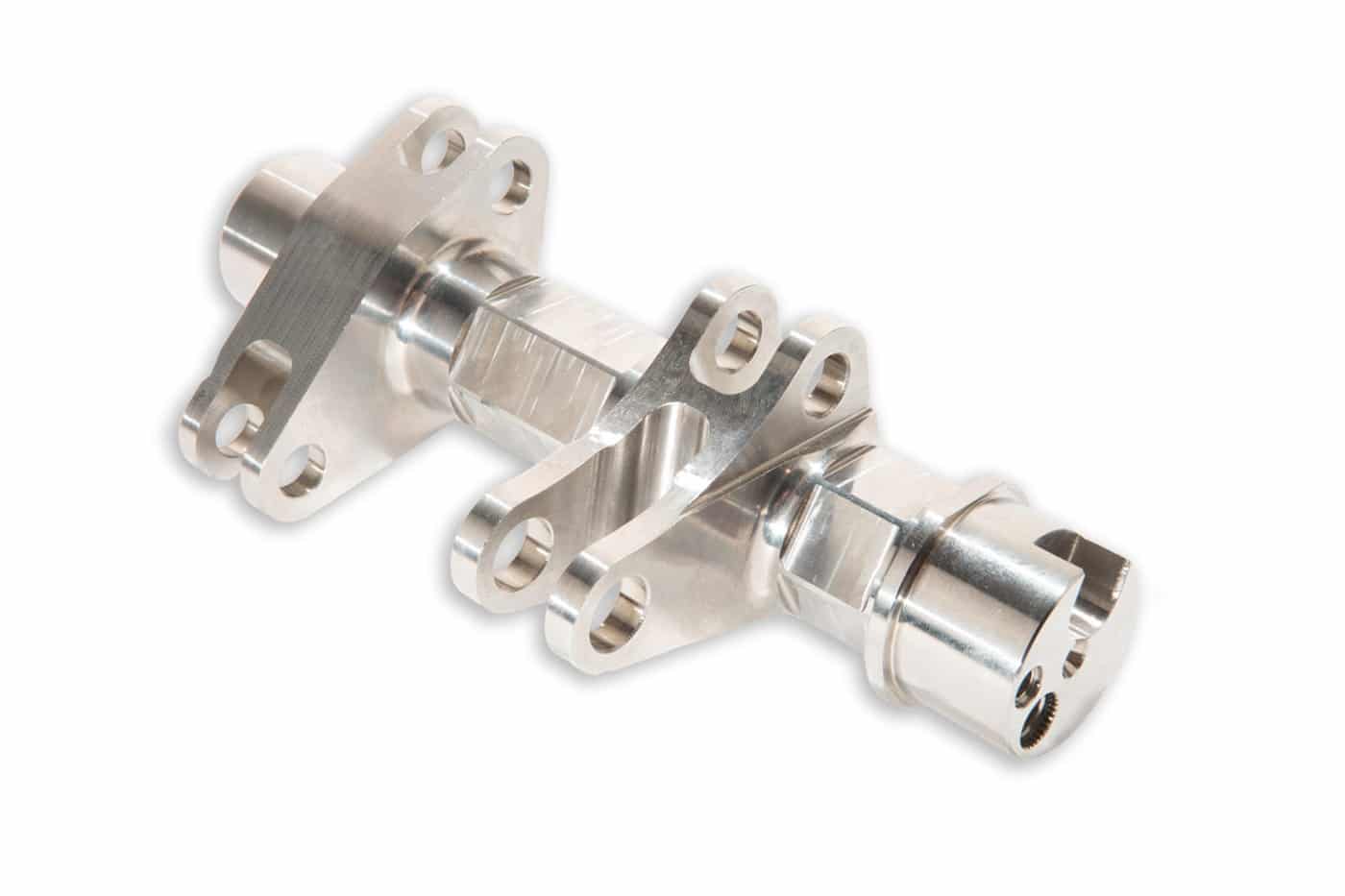

For the pivot points to which the baggage racks are attached to the airframe, we rely on a combination of various materials in order to achieve ideal function with the lowest possible weight, true to the concept of lightweight construction. The clip system allows an easy and quick installation and removal of the luggage rack.

The oil damper is equipped with our innovative AEROLIFT® system, which offers a fluid damper movement and a significant reduction of the “stutter effect” thanks to a new valve system. A pressure relief valve serves as protection against overload and abuse.

RELIABLE CLOSING AND OPENING MECHANISM FOR THE AIRCRAFT CABIN

We develop, test and manufacture components and assemblies for various overhead storage locking mechanism concepts and designs. The technical specifications of our customers enable us to provide unique solutions using state-of-the-art materials and processes including additive manufacturing.

AEROSHOCK® DAMPING ELEMENTS – REDUCE NOISE & VIBRATION IN THE AIRCRAFT CABIN

RO-RA designs and produces shock mounts comprise from machined and milled metal parts coupled with shock-, noise- and vibration damping, temperature insulating elastomer components. As standard we offer axial and radial applications with a stiffness varying from 25 N/mm to 4.500 N/mm. A wide range of amplitudes and end stops are designed according to customer requirements.

PRECISE AND FUNCTIONAL MECHANISMS FOR THE AEROSPACE INDUSTRY

WE OFFER CUSTOMIZED SOLUTIONS!

In addition to highly complex connecting elements and precision components for the engine and wing area RO-RA manufactures various mechanisms and dampers for luggage racks and the cabin interior. The combination of pivot point kinematics with the appropriate damper guarantees a perfect interaction of these components.

The following core competences of our product and process development enable us to deliver an innovative product in accordance with the latest technical standards.

The product and process development includes:

- 3D CAD Modeling & 2D Engineering

- Strength verification with FEM simulation

- Consistent implementation of the lightweight design concept with CAE and topology optimization

- A final compression and tensile load analysis including appropriate tests

- cyclic fatigue tests

- Free rotation analysis including corresponding tests

- Weight Evaluations

- Environmental tests according to industrial standards or individual customer requirements.

RO-RA AVIATION SYSTEMS, YOUR PARTNER FOR AFTERMARKET COMPONENTS IN AVIATION.

- Components manufactured to the highest standards

- 3D printing for rapid prototyping

- In-house engineering and test facilities

- Fully EASA- and FAA-certified aftermarket parts are available with either EASA Form 1 or FAA 8130-3 certificates of airworthiness

RO-RA Aviation Systems is Austro Control (EASA) POA certified

YOU NEED DETAILED INFORMATION?

WE ARE ALWAYS THERE FOR YOU!

Further products from RO-RA

High Presicion Components Engine

Solenoids / Brackets, Complex Turned & Milled Parts, Bellcranks / Crankshafts, Rigid Pipes / Rings